We process steels, stainless steels, aluminum, bronze, brass and plastics.

Our machinery:

> 14 Turning centers

> 11 Milling centers

> 1 Tangential adjustment

> 1 Dynamometer for testing

> 2 Three-dimensional measuring machines

> 3 Automatic cutting-off / sawing machines

> 7 Assembly islands with press and coders

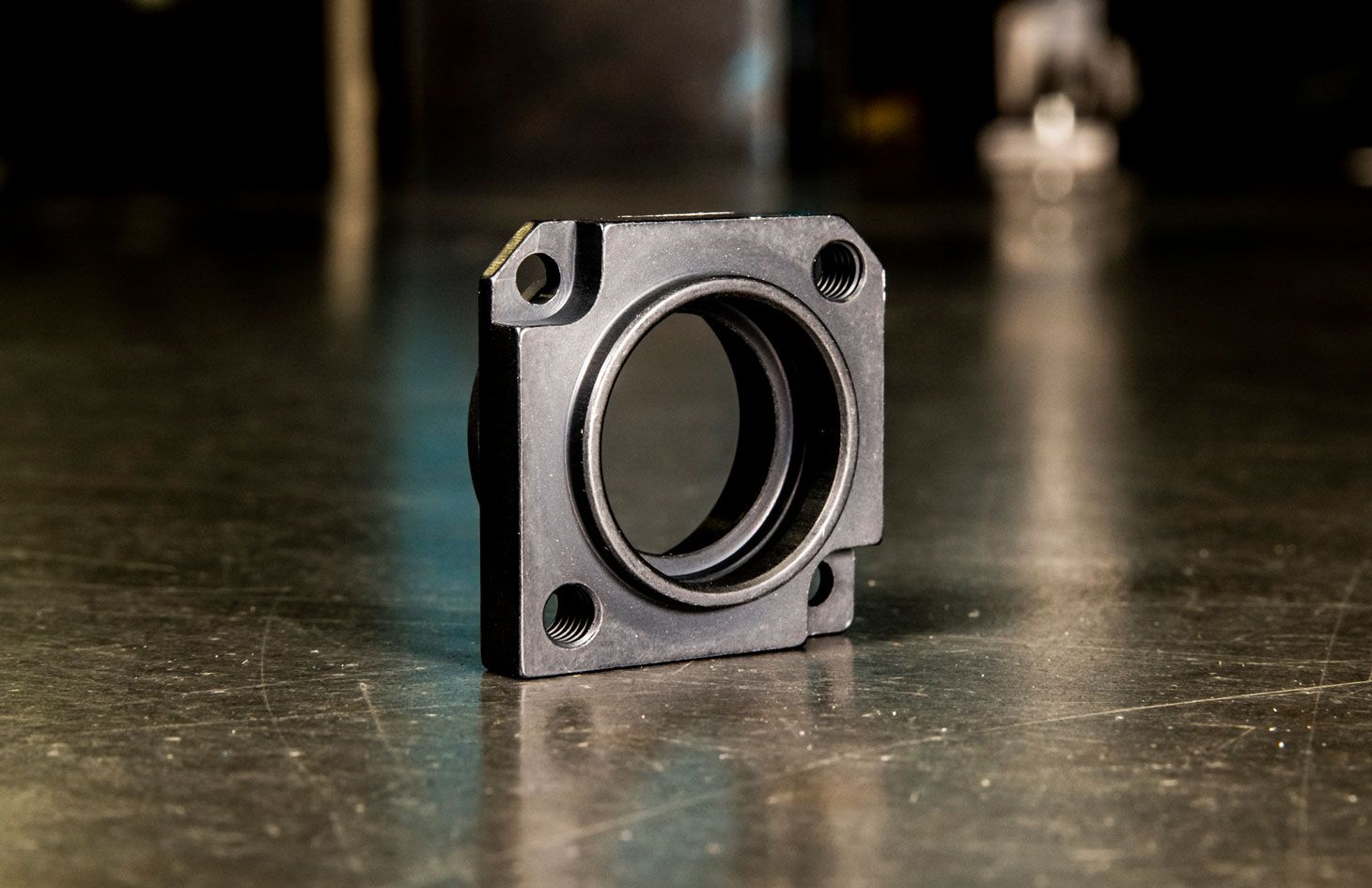

Turning

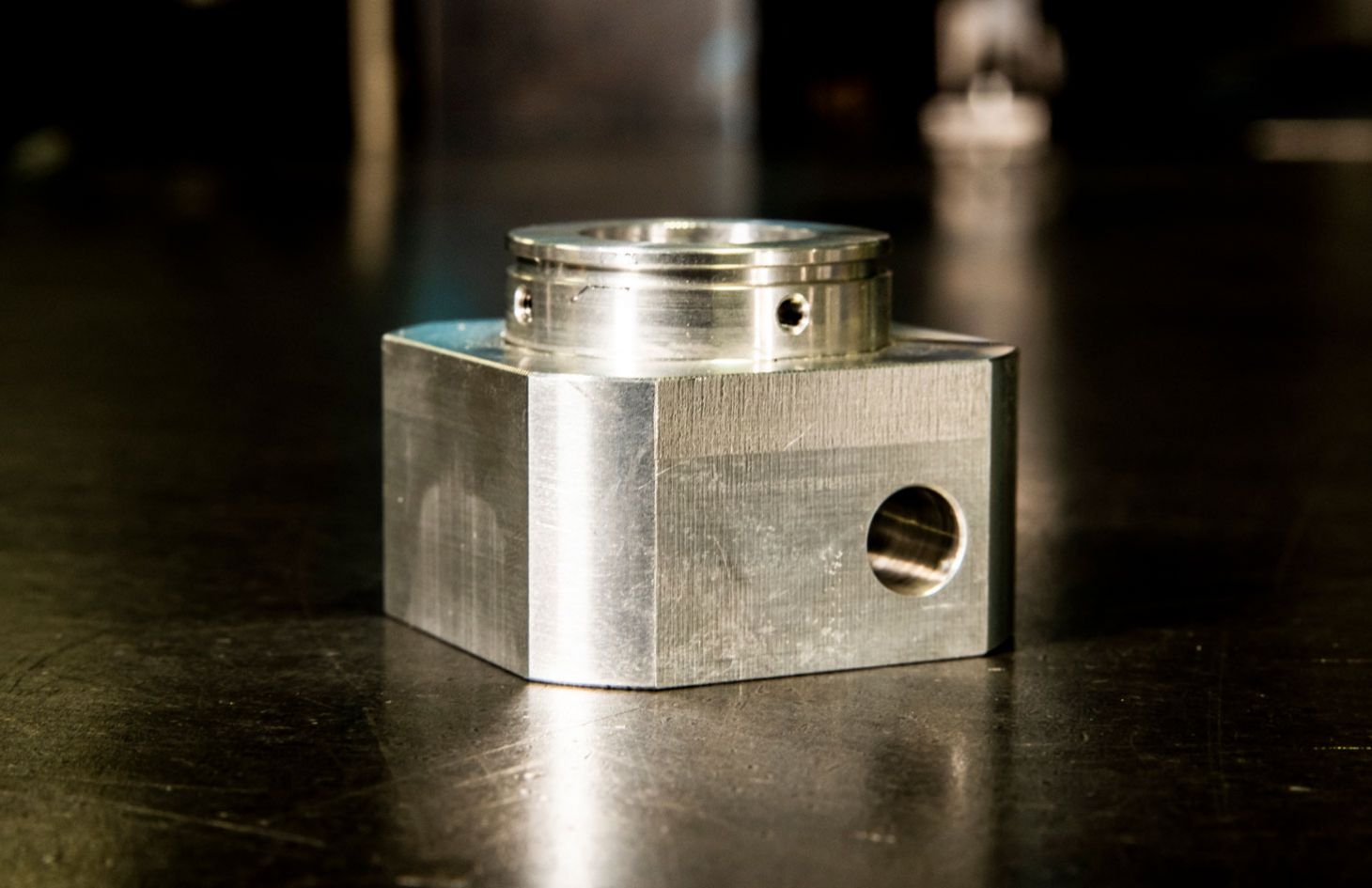

Milling

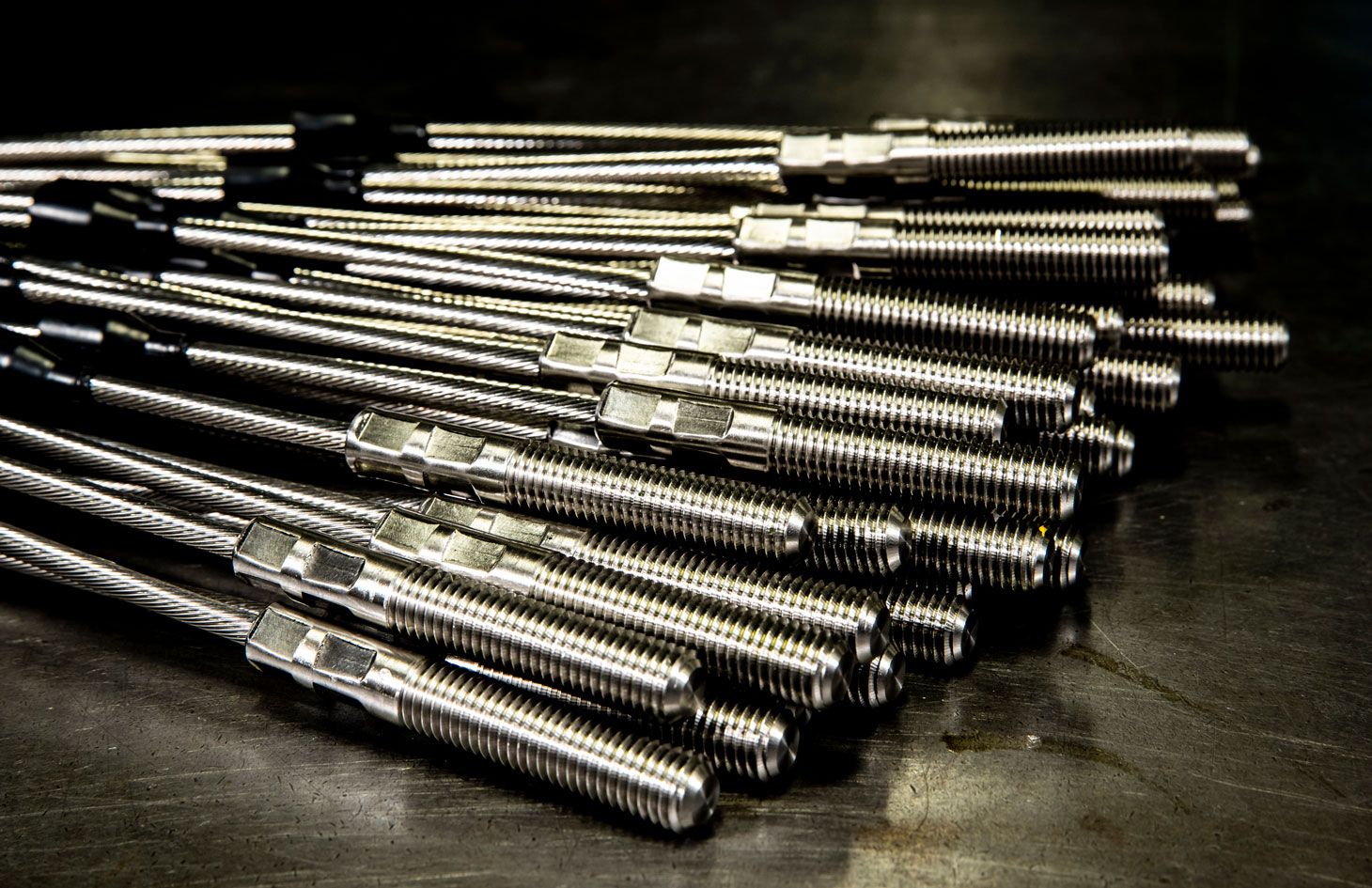

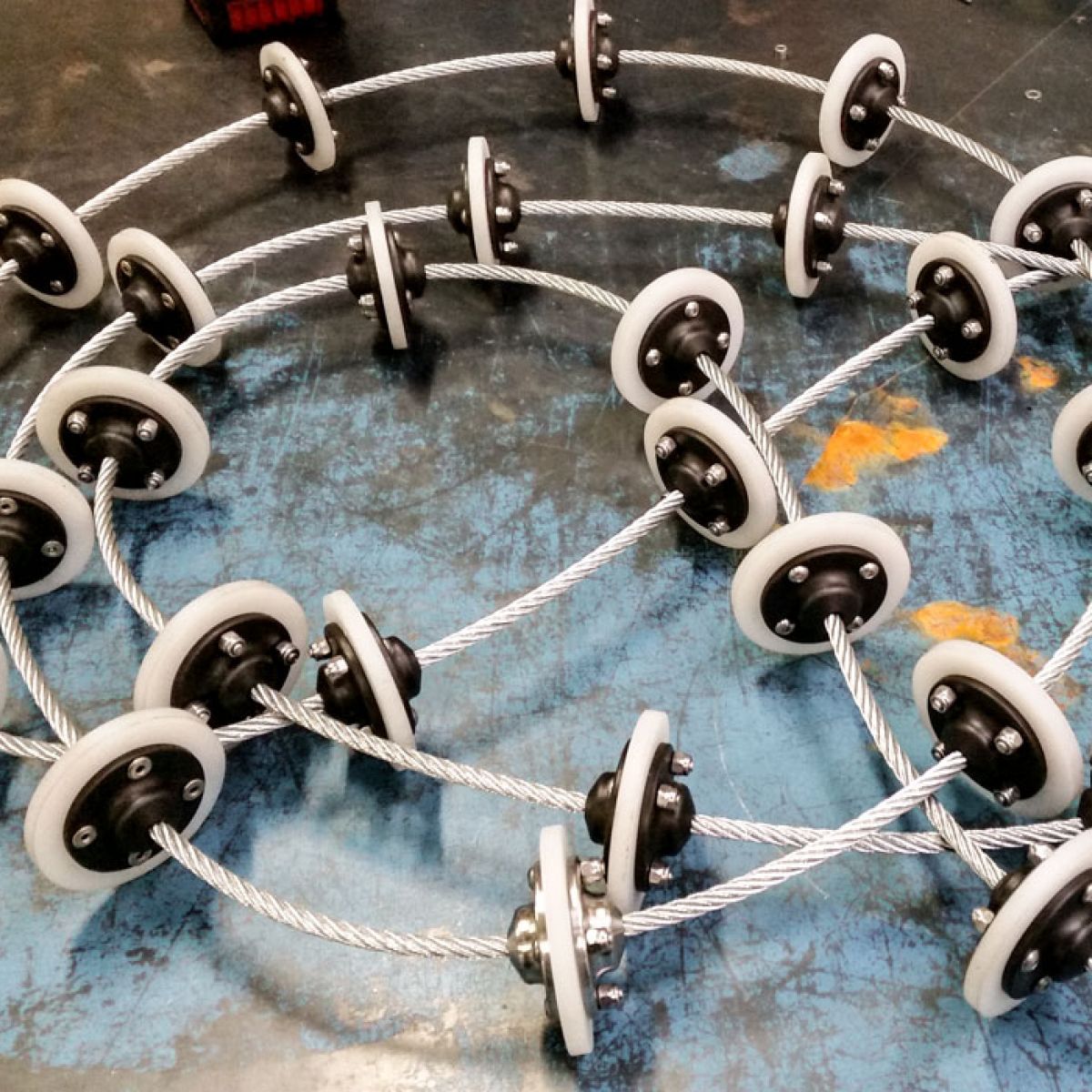

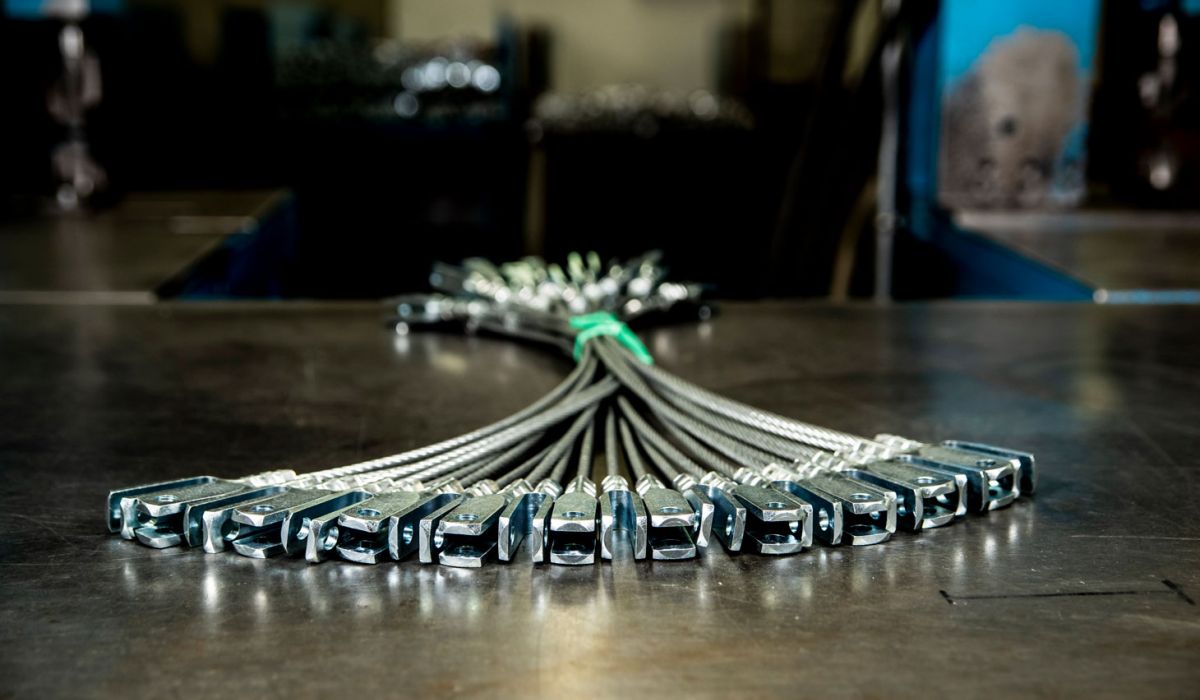

Cable and Flexible Transmissions

Assembly islands

Personalizations